0% for 36 Months or 10% off a New AC. Learn More >

HVAC Ductwork Replacement in Austin

Repairing or replacing your ductwork, when needed, is essential for maintaining optimal performance of the overall HVAC system. However, ductwork is a complicated subject that is sometimes treated like an afterthought. Marketing is largely focused on machine, machine, machine, or brand, brand, brand. In reality, any reputable brand in each product tier performs well and lasts long. The differences are generally slight in performance, warranty, specifications and price. Differences in product support are a bit larger.

There are many factors that go into HVAC ductwork replacement. In this guide, we’ll cover:

Table of Contents

HVAC Ductwork Sizing

Duct design starts with sizing, and sizing starts with a load calculation. Each branch and trunk must be sized to ensure low noise but enough velocity to move air into the space. The machine type (variable or fixed) and specifications also play into the calculations.

The duct material and number of turns also affect each duct run’s size. For example, flexible duct and how stretched it is at installation affects the needed diameter, while stretching is not a factor when sizing steel duct.

HVAC Ductwork Materials and Components

Typical residential ductwork is built with these main materials and components:

- duct board for trunks

- flexible duct for runouts (hopefully short)

- dampers for adjustment

- steel Y’s and insulation to split air, if needed

- straps or hangers

- buckets for grilles

- grilles

- mastic (sealer)

The proof of well-designed HVAC ducting is that it can be adjusted (balanced) and tested to be virtually leak free while achieving the air required at each grille with minimal noise.

Insulated (internal or external) steel is generally not used for residences, as it is more expensive and more difficult to install correctly. One exception is ductwork under a pier-and-beam home.

Under-home ductwork – which is exposed to outside conditions and, more importantly, pests – should be constructed of lined steel and protected such that pests cannot chew it. Steel is effective in keeping rodents out. It can also be used in more expensive applications. Compared to flexible duct, it is a higher quality product that provides more durability and rigidity in areas that are susceptible to damage and sagging, and it also results in less air loss due to friction. Efficient can design, fabricate and install a residential duct system composed of metal ductwork, utilizing flexible duct and ductboard as needed. It doesn’t have to be all metal or none.

Steel is typically required in all commercial and industrial applications and specified by engineers. It should be made to SMACNA (Sheet Metal and Air Conditioning Contractors’ National Association) standards. Typical metals used range from 18-gauge to 26-gauge G90 galvanized steel. For special applications, ductwork can be made of black iron, high temperature venting, aluminum, stainless steel and even fabrics.

Ductwork Installation Workmanship

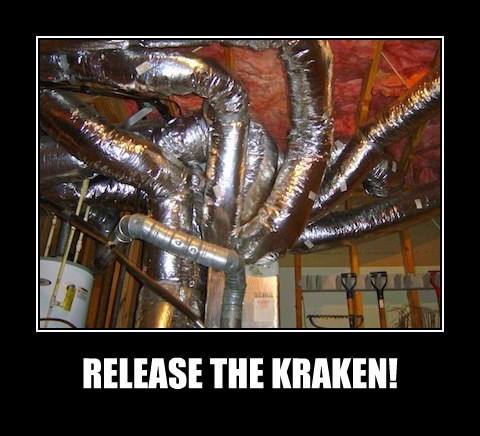

Appearance is also important and is a sign of good workmanship. A long, clean trunk with regularly spaced runouts, 18 inches (or close) before the first tap (attachment) and after the last is the standard, with clean run outs to the grilles. Straps should not pinch or crimp the ductwork. Mastic should be applied to all joints liberally, uniformly and neatly. The net result should not look like a confused octopus.

Other Factors

Other factors are typically those that affect air flow and balancing. The best duct system and highest rated equipment cannot overcome a serious air balance issue. One enormous kitchen hood run for long periods of time with no dedicated make-up air path (air to replace what is being exhausted out) will destroy HVAC system performance. Continuously running bath vents will cause the same issue. Infiltration into the property or excess moisture generated within the property with no escape will also not be cured by good ductwork. Factors such as make-up air, dehumidification and air balance for neutral or positive air pressure must be part of the solution.

What Are the Benefits of Properly Installed Ducting?

The benefits of properly designed and installed ductwork are both in comfort and efficiency. An excellent duct system will deliver consistent temperatures across the areas or rooms – even more so with zoned systems. Such a system will have minimal air loss and will deliver all the airflow and thermal capacity to the intended areas. In general, low air loss means low electric bills.

What Is the Life Expectancy of Ductwork in Austin?

Conventional residential duct systems using ductboard and flexible insulated duct will last 30 years or more with current materials in attics and walls. More often than not, duct system deterioration is due to damage and poor conditions. Duct runs in heavily used areas (attics used for storage, for example) often become damaged. Conventional ducting run under a home will also not last long and is susceptible to damage from pests. Wrapped metal duct can last much longer – perhaps the life of the home itself. Even with this, the external duct insulation will have a life similar to conventional ducting and will need to be replaced when damaged – or perhaps in 30 years.

How Much Does HVAC Ductwork Replacement Cost?

Duct replacement cost varies. For conventional ductboard and flexible duct installations, replacing the entire duct system will cost several thousand dollars. For rough budgeting, plan $500-600 per grille. For example, a home with 10 grilles on one HVAC unit will cost between $5,000 and $6,000 for a full replacement. However, in many cases, a full replacement is not needed, and a few runs will make the system perform optimally. At Efficient, we will provide a complimentary quote for whole or partial duct system replacement, so no guesswork is needed.

Is It Worth It To Replace HVAC Ducting?

Every home is different, so the answer depends. We often find good duct systems needing no repair or replacement, or perhaps just partial. If the ductwork is poorly designed or in poor condition, absolutely. The most expensive highest efficiency HVAC system will not overcome poor ducting. In this case, it is much more advisable to spend money on the duct system and pick a less expensive HVAC system.

Austin Air Duct Replacement: Our Process

- Assessment/Proposal: Efficient’s process starts with a physical assessment and proposal tailored to your specific home and system. While sometimes an HVAC unit replacement can be quoted over the phone (simple replacements), duct system repair or replacement cannot. Ductwork replacement is completely driven by the unique property. We may need to take readings, measurements, assess feasibility and access, and consider your desires. This requires some level of duct design, ensuring that the runs are designed for best airflow, sized appropriately and have means of adjustment. Efficient’s service manager or a lead technician will assess your needs. They will bring the information back to our office, and we will then prepare a proposal – at no charge to you – that meets those needs. If custom metal work is needed, we can fabricate it in our shop. We are not limited to off-the-shelf solutions.

- Scheduling: If you choose to move forward, we will schedule a crew to complete the work on a day that fits your schedule. Each HVAC system will be down for the better part of the day for full replacements.

- Clean Up: Our installers will haul off old materials and systems unless otherwise directed by the property owner. Rest assured that we work with recyclers to properly reclaim refrigerants and recycle everything that can be recycled. As a side note, Efficient does not profit from selling recycled materials; however, there are several happy recyclers in the area who earn their living by doing so. It is not the easiest way to make money, and we appreciate them for it.

- Warranty: When your ductwork replacement is complete, we’ll stand behind it with a 1-year warranty on parts and labor. This warranty covers any disconnections or leaks at connection points (excluding damage from external factors like rodents or water).

As you can see, ductwork replacement is an involved process, and there is some inconvenience involved (no air conditioning for the day), but it’s worth it. To get started, fill out our quick form or give us a call at 512-501-2275.